We will strive to design new products through the innovative use of renewable, reusable, recyclable and biodegradable materials. We will have a centre of excellence where we can showcase products to our customers, and provide a space for ideas to flourish into innovative new products.

Transitioning to more sustainable materials

Our focus and targets

50% of raw materials from sustainable sources by 2030 across our polymer ranges.

100% of raw materials from sustainable sources by 2030 across our general protection and security seal ranges.

In 2023, we hit our 2025 target early, achieving 20.7% of sustainable materials in our polymer ranges.

In 2020, we signed up to the Circular Plastics Alliance commitment to use at least 20% recycled content in our polymer ranges by 2025. We have achieved our target early, developing our use of recycled content during the year to 20.7% for 2023. Consequently, we have set a new target to achieve 50% of raw materials from sustainable sources across our polymer ranges, and 100% in our general protection and security seals ranges by 2030. In 2023, we have increased the number of products and sites that have transitioned to using recycled content in our polymer ranges. We now have seven manufacturing sites globally where recycled content is used as standard, across a range of over 7,000 products.

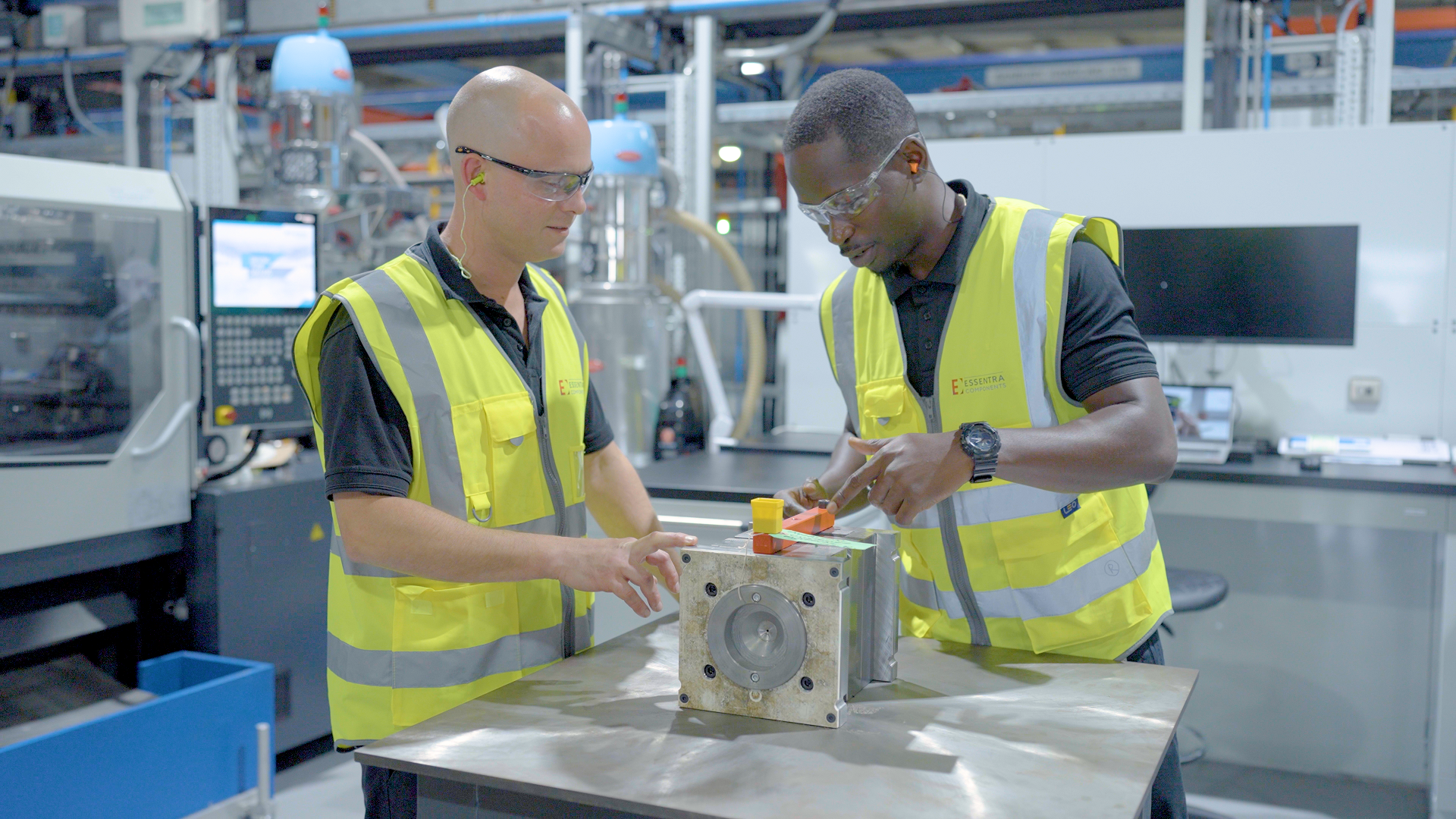

Our Centre of Excellence

In 2023, we launched our Centre of Excellence to support our transition to using more sustainable materials across our product range. This dedicated centre at our Kidlington site in the UK, is used to trial a wide array of materials with sustainability benefits such as reduced emissions, improved recyclability and improved circularity. These innovative new materials can reduce the environmental and carbon impact of the products we manufacture, and helps our customers reduce their GHG emissions.

The principal purpose is to enable us to test not only how the materials will behave in the manufacturing process, but also the impact of different types of tooling. The results will provide us with the tool to drive efficiency and sustainability in our products and processes, reducing scrap rates and accelerating speed of delivery. The Centre of Excellence is an example of how sustainability is embedded in our culture. We are investing significantly in new infrastructure and equipment, allowing us to test and process new types of materials, and optimise energy consumption.

Our Packaging

Our focus and targetsSupport a circular economy by ensuring

100% of our packaging is reusable, recyclable or compostable by 2030.

50% recycled content in our packaging materials by 2030.

Support a circular economy by ensuring

58% of our packaging is reusable, widely recyclable or compostable.

28% recycled content in our packaging.

Packaging is an important part of our resource usage and is key to ensuring our products are delivered damage and hassle free to our customers. 2023 is the first year since we introduced packaging targets, and during the year we have been engaging with our packaging suppliers to determine the current rates of recycled content in our packaging, and to explore opportunities to reduce packaging and waste. At the end of the year, we reached 28% recycled content across all of our packaging, and 58% of our packaging is deemed to be widely recyclable or compostable. We have included paper and wood in our scope of what we determine to be widely recyclable, or compostable. In 2024, we will be continuing to engage with our packaging suppliers to share best practice and increase recycled content.